The EPP35 riot shield by NIDEC is the safe choice for crowd control, thanks to its exceptional strength and adaptable design. Its high-quality polycarbonate construction resists torsion and heavy impacts.

Discover the revolutionary EPP35 reinforced riot shield from NIDEC, specifically designed to meet the demands of various departments. This robust shield features a 0.3cm thick polycarbonate plate reinforcing the entire grip area. Plus, its vertical sides are slightly curved inward, offering enhanced strength and protection.

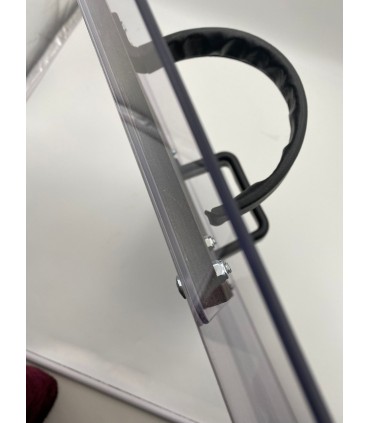

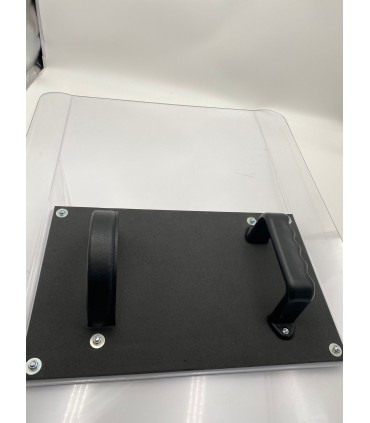

The EPP35 boasts an innovative grip system with quick-release handle and clamp, adjustable for left-handed and right-handed users. Its curved sides form rectangles of 6.7cm wide by 110cm long, and an additional 440x270x3mm thick reinforcement polycarbonate plate adds firmness.

Made with a unique composition of high-quality polycarbonate resins, this riot shield outperforms conventional polycarbonate models as it can resist torsion without breaking. While other shields may shatter and become potential bladed weapons, NIDEC's EPP35 bends and returns to its original shape, providing unparalleled safety for the field agent.

With resistance to an impact of 150J of kinetic energy and more than 20J of punch kinetic energy, NIDEC shields are the safe choice for crowd control.

GENERAL CHARACTERISTICS

- Manufactured in state-of-the-art polycarbonates that offer greater resistance to chemical agents, pressure and lack of visual distortion when looking through it.

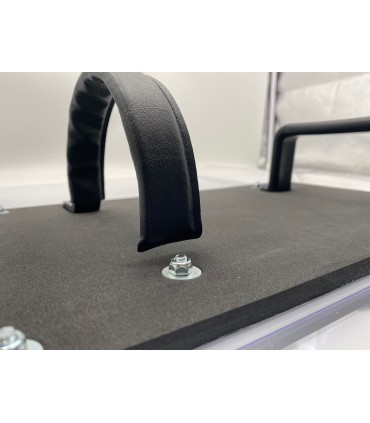

- Ergonomic grip with finger indentations, highly durable non-conductive polypropylene handle and Velcro closure for quick release.

- Rounded edges and no sharp edges.

- High-density EVA foam forearm support padding.

- Flat surface shield with inward folded sides giving a convex shape to the shield which allows for improved protection of the riot officer as the flexibility of the shield is reduced.

- Ambidextrous. The user himself can change the side of the shield's handle and clamp with a simple tool.

- 5-year warranty against any manufacturing defect of the polycarbonate.

- Allows video recording from behind the shield without causing distortion.

CHARACTERISTICS OF POLYCARBONATE

- Polycarbonate density: 1.2 g/cm3 per ISO 1183.

- Humidity (after drying at 23º in a conditioned environment according to ISO 62-4): 0.15%.

- Molding temperature: 180-210 ºC.

- Flexural strength ISO 527-2: 60 Mpa.

- Deformation by bending ISO 527-2: 6%.

- Tensile strength ISO 527-2: 60 Mpa.

- Elongation before rupture ISO 527-2: 70 Mpa.

- Charpy impact test with notching ISO 179: No breakage kj/m2.

- Vicat softening properties ISO 306: 148 ºC.

- Thermal transmittance DIN52612: 0.2 W/mK

- Thermal linear expansion DIN53752-A: 0.065 mm/mC.

- Thermal deflection temperature at 0.45 MPa. ISO 75-2: 139 ºC.

- Specific heat capacity: 1.17 J/gK.

- Light transmittance DIN5036-3: 86%.

- Optical refractive index ISO 489: 1.586.

- Electrical-volumetric resistance IEC 60093: 10 üzeri 10 Ohm.cm.

- Dielectric voltage IEC 60243-1: 35 kV/mm

- Electrical surface resistivity IEC60093: 10 üzeri 14 ohm

- Dielectric constant (above 10 3 Hz) IEC 60250: 3,1

- Operating temperature from -50 C to +50 C

- Anti-scratch and anti-fog treated

PHYSICAL CHARACTERISTICS OF EPP35

- Dimensions: 1100 (+-10) x 585 (+-10) x 4 mm thick (+- 0,5)

- Weight: 3.9 kg.

- Other models such as the smaller EPP22 are available.

- We also have special models up to 0.7 cm thick, with V50 anti-fragmentation certification up to 260 m/s.

- Optionally they can be supplied with Nylon sheath for shield protection.

- The shields do not include any type of labeling. We have RPP25 signs with the letters: POLICIA, POLICIA LOCAL and POLICIA MILITAR. Others, please consult us.

Leave a review